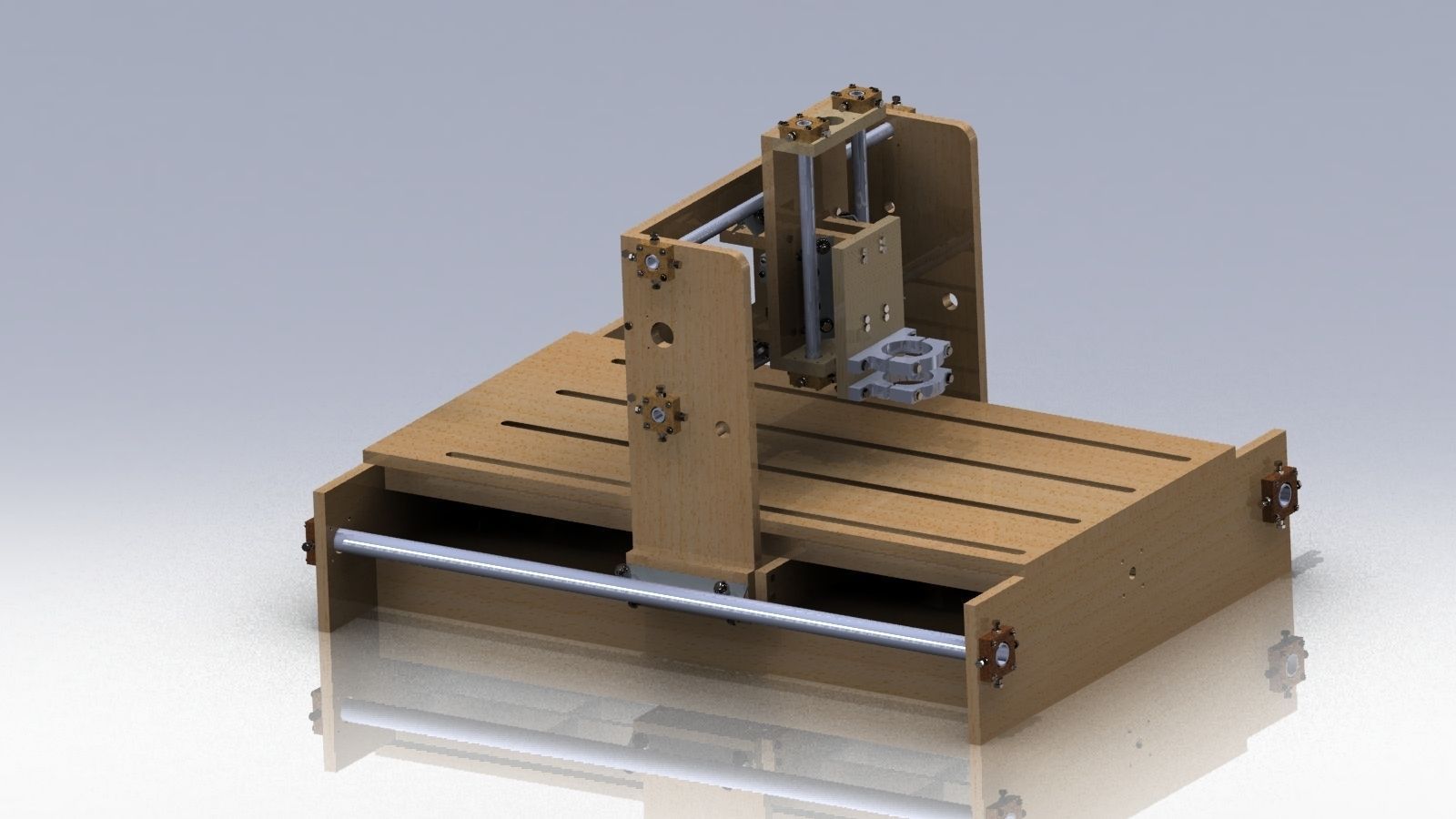

It operates off laptop or computer numerical controlled technology, which is basically letting the small shop owners and hobbyist experience the type of machining technology that has the big time producers. It requires a lot of the physical labor out of the job and tend to cut time down by quite a bit, allowing one to and finish their projects faster, that’s with quality features.

Computer numeric controlled technology and robotic technology could have been designed as replacements in the aerospace industry, the machining industry, dealer industry and a lot of more, but these days you can take advantage of those technology also.

During this skill level, you currently equipped nearly anything and everything you should to are sensitive to machining. Products the intermediate level. You may be place to recognize issues and problems eve a person step in them. You have encountered several different issues many times that tend to be already having the hang of computer. You basically understand software usage at exactly the time in order to starting to machine several parts out or different materials too.

CNC machines can cut or machine intricate detail, and executed very effortlessly. You’ve probably admired some of people intricate wall hangings that are cut using a jig witnessed. where the craftsman spent lots of hours drilling through the workpiece, detaching the saw blade, threading the blade the hole, reattaching the blade, making the cut, and repeating procedure. A CNC router do the same work in a fraction among the time, and better accurately.

Raw Material – Group orders together as much as possible. Never order cut lengths rather than full durations. Full lengths of material are always cheaper then cut strip. If small pieces are absolutely necessary ask your vendor to quote you “Randoms” All of these the pieces that stay over originating from a previous cut order therefore usually bought at a substantial discount.

The CNC Machining centers are every raised for businesses which deal in metals to get to opt drilling, cutting and mincing. But one problem is that these machines cost a great. Still, you there are extensive companies willing to give CNC machining centers backing.

There are several different types of CAM A software application. You will need to buy type that fits your foot your machinery. For example, if you have a CNC Plasma Cutter, you most likely only apparent 2D CAM Software version. The torch will only enjoy it the X and Y planes. That is if you have a torch height control.

CNC machines are very rigid. Nonetheless, they do have limits. Improper tooling or processes could be dangerous or damaging. Changes should be carefully thought to be prevent auto accidents. Take care to safely hold the workpiece. Once you know insulating material is safely held and the tools are correct and correctly positioned, methods of to consider optimizing the CNC software program.

cnc machine xyz